Project introduction

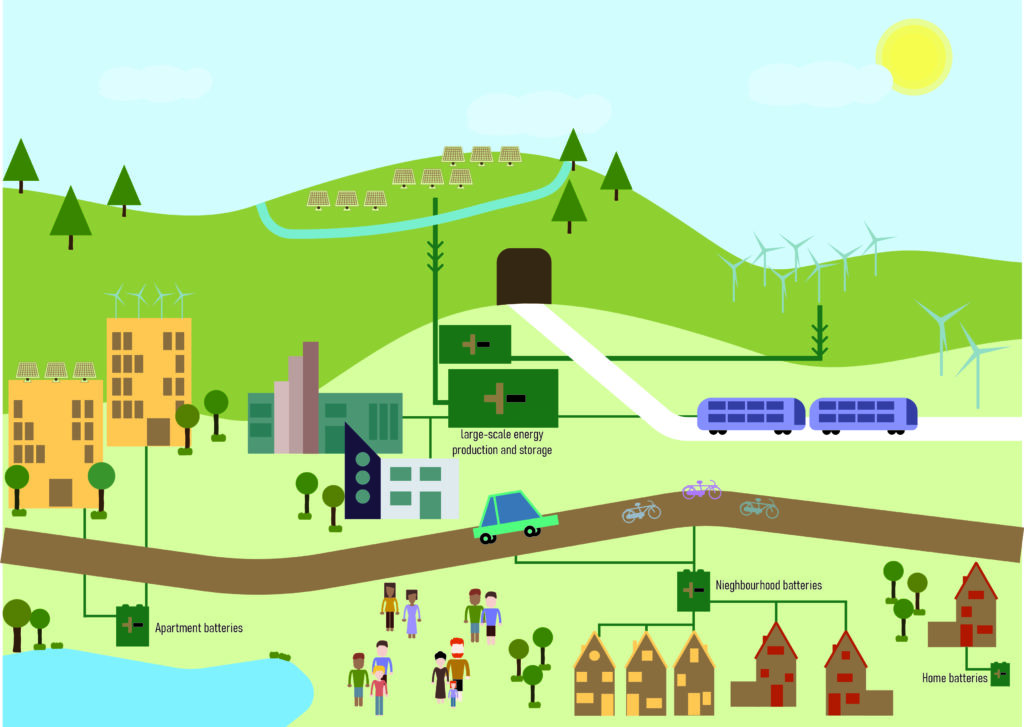

Energy storage systems, in particular, batteries, are key technologies in the transition towards a carbon neutral society. Due to the growing electric mobility market, lithium-ion batteries (LIB) are produced at increasingly large scale resulting in large cost reduction and new opportunities for their implementation in energy storage at grid and/or household level. By 2040, it is expected that the number of electric vehicles will increase two to three orders of magnitude and stationary storage may reach up to 1300 GWh, compared to 3-4 GWh installed in front-of-the-meter today. This leads to concerns about the future and long-term availability and cost of critical raw materials (cobalt, nickel, lithium and copper) employed in LIB. Although LIBs are excellent candidates for the electro-mobility application, Europe still needs new generations of high performance, reliable, safe, sustainable and affordable batteries for stationary storage. In Sodium Ion (SIB) and Sodium Metal (SMB) batteries, the critical materials employed in LIBs can be replaced with widely abundant and sustainable materials paving the way toward greener, more sustainable, lower cost next generation energy storage technologies.

![]() The SIMBA project main goal is the development of a highly cost-effective, safe, all-solid-state-battery with sodium as mobile ionic charge carrier for stationary energy storage applications. Although in many ways SIBs are similar to LIBs, there are still a number of persistent scientific and technical challenges to be addressed in understanding electrochemical processes and degradation mechanisms, electrode, solid-state electrolyte and cell manufacturing. SIMBA aims to solve these challenges and pave the way to market introduction. In terms of customer value, it will target the product market space between LIB and lead-acid batteries, offering similar performance advantages of LIB (high efficiency, low volume and weight) but with the cost-advantage of lead-acid (low material cost and ease of recycling).

The SIMBA project main goal is the development of a highly cost-effective, safe, all-solid-state-battery with sodium as mobile ionic charge carrier for stationary energy storage applications. Although in many ways SIBs are similar to LIBs, there are still a number of persistent scientific and technical challenges to be addressed in understanding electrochemical processes and degradation mechanisms, electrode, solid-state electrolyte and cell manufacturing. SIMBA aims to solve these challenges and pave the way to market introduction. In terms of customer value, it will target the product market space between LIB and lead-acid batteries, offering similar performance advantages of LIB (high efficiency, low volume and weight) but with the cost-advantage of lead-acid (low material cost and ease of recycling).

Project Concept

The overall concept and approach of SIMBA comprises the following conceptual elements: development of two anode and two cathode materials and a novel Solid-State Electrolyte (SSE). Together with new modelling and characterisation techniques, the main challenges of SIB will be addressed effectively. Two environmental-friendly production methods will be applied to the new materials which will advance the state-of-the-art technology to put SIB on the path towards low-cost, efficient and scalable stationary energy storage.

The main ideas behind the concept and main innovations are:

- The deep understanding about the interaction between the solid-state electrolyte and the electrodes are at the centre of the development process

- Development of two anode and two cathode materials.

- Reach a high level of sustainability investigating new recycling strategies, including developing, dismantling, and remanufacturing procedures to re-use the materials in new cells.

- Ensure a fast route to deployment by development of two different production methods and scaling up the selected materials to the kg-scale required to build a final battery module including BMS.

The complexity of the SIMBA objectives makes it necessary to operate the project with specialists along the value chain spanning from advanced materials suppliers, production technology providers, battery manufacturers, and end-users to end-of-life and sustainability experts. This requires the involvement of partners having diverse, complementary and interdisciplinary backgrounds expanding well beyond the strictly technological domain.

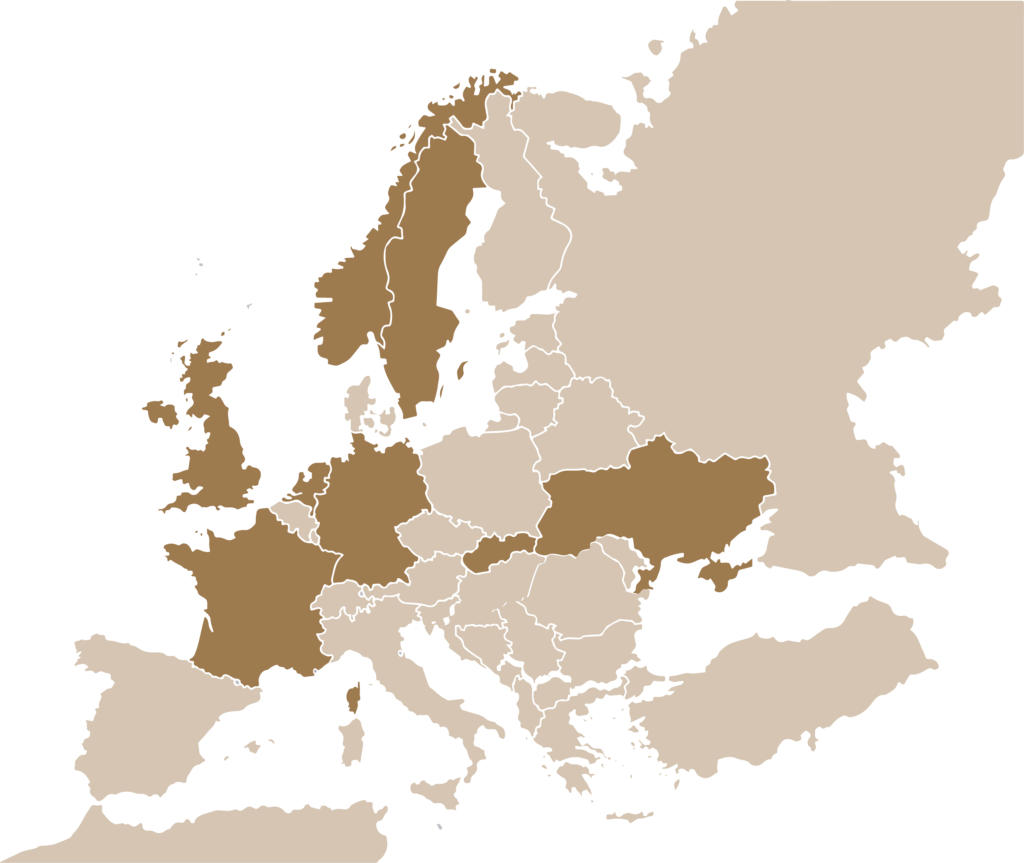

The SIMBA consortium consists of 16 partners from 7 European countries and one associated country.